- SATA cables

- Mini SAS SFF 8087 cables

- Mini SAS SFF 8088 cables

- Mini SAS SFF 8643 cables

- Mini SAS SFF 8644 cables

- M.2(M-Key NVMe 2260) cables

- Slim SAS SFF 8654 4i cables

- Slim SAS SFF 8654 8i cables

- MCIO PCIE Gen5.0 cables

- SFF 8611 Oculink 4i cables

- SFF 8611 Oculink 8i cables

- Slim SAS LP low profile SFF 8654 8i cables

- Mini SAS SFF 8088 8I 8X cables

- CAB STACK E SAS HD 32pin cables

Categories

- SATA cables

- Mini SAS SFF 8087 cables

- Mini SAS SFF 8088 cables

- Mini SAS SFF 8643 cables

- Mini SAS SFF 8644 cables

- M.2(M-Key NVMe 2260) cables

- Slim SAS SFF 8654 4i cables

- Slim SAS SFF 8654 8i cables

- MCIO PCIE Gen5.0 cables

- SFF 8611 Oculink 4i cables

- SFF 8611 Oculink 8i cables

- Slim SAS LP low profile SFF 8654 8i cables

- Mini SAS SFF 8088 8I 8X cables

- CAB STACK E SAS HD 32pin cables

Right angle 90 degree PCIE Oculink SFF 8611 4I To SFF 8644 High-Speed Connection cables

Specifications:

- right angle Oculink SFF 8611 4I To SFF 8644

- Gold plated connectors

- Conductor: TC/BC (bare copper),

- Gauge: 28/30AWG

- Jacket: Nylon or Tube

- Length: 0.5m/ 1m or others. (optional)

- All materials with Roshcomplaint

- Product Detail

- Product Description

- Custom Services

Warranty Information

Part number JD-I022

Warranty 1 Year

Hardware

Gender PCIE Oculink SFF 8611 4I

Cable Jacket Type HDPE/PP

Cable Shield Type Al foil

Connector Plating Gold plated

Connector(s)

Connector A Oculink SFF 8611 4I

Connector B SFF 8644

Physical Characteristics

CableLength 0.5M

Color Black

Connector Style Straight

Product Weight

Wire Gauge 32 AWG

Wire Diameter

Packaging Information

PackageQuantity 1Shipping

(Package) Weight

Maximum bandwidth

Right angle Oculink SFF 8611 4I To SFF 8644

Gold PlatedColor Black| Electrical | |

| Quality Control system | Operation according to regulation & rules in ISO9001 |

| Voltage | DC300V |

| Insulation Resistance | 10M min |

| Contact Resistance | 3 ohm max |

| Working Temperature | -25C—80C |

| Data transfer rate | 12G |

Applications:

OCuLink SFF-8611 cables are widely used in HDTV, Computer, ServerInterface

OCuLink SFF-8611 4I interface is a high-speed interconnection standard released by the PCI-SIG, mainly used for connecting the motherboard to external devices such as SSDs, GPUs, and adapter cards. It supports PCIe 3.0/4.0/5.0 protocols and enables high-speed transmission via copper or optical cables.Detail

The internal wires are usually made of high-quality copper, which has good electrical and thermal conductivity to ensure stable and efficient data transmission. The exterior is wrapped with an insulating material, usually polyvinyl chloride (PVC) or other materials with good insulating properties, which protects the internal wires from the external environment and also prevents short circuits and other problems between the cables.Ultra durability and shielding performance

The connector shell and contact part will usually use metal materials, such as brass, phosphor bronze and so on. These metal materials have good electrical conductivity and mechanical strength, to ensure a stable connection between the connector and the equipment, and can withstand multiple insertion and extraction and not easy to damage. Metal shell can also play a role in shielding electromagnetic interference, improve the stability of signal transmission.Why Choose Our Customization Service?

Tailored to Your Application

We offer a wide range of customization options including cable length (from 0.2 m to over 10 m), wire gauge (28 AWG/32 AWG), jacket material (nylon, PVC, TPE), color, and labeling. This ensures the cable perfectly fits your hardware setup, installation space, and branding needs.

Flexible Connector Configuration

Beyond standard SFF-8643 and 4× SFF-8482 interfaces, we can adjust connector types and layouts — such as angled or straight plugs, power connector positioning, or hybrid outputs compatible with SAS and SATA — to guarantee seamless integration with your servers, HBAs, and backplanes.

Guaranteed Quality & Performance

All customized solutions maintain our high standards with gold-plated contacts and bare copper conductors, RoHS compliance, and support for up to 12 Gbps transfer rates. You can rely on excellent signal integrity, durability, and EMI resistance.

Fast Response & Scalable Orders

From technical evaluation to sample approval and mass production, we provide an efficient process. Small-batch prototyping and flexible large-volume orders are available to match your project timeline and production needs.

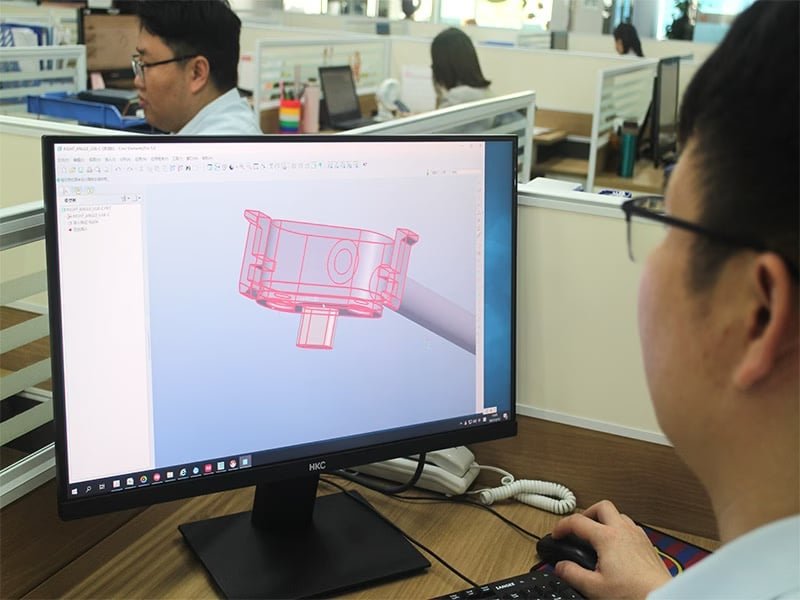

Custom Design Processing

Requirement Collection

Share your application details, including server type, interface specifications, cable length, and special requests.

Engineering Evaluation

Our R&D team analyzes your requirements and provides a tailored design proposal with technical drawings and material options.

Sample Development

Rapid prototyping and sample production are carried out for performance testing and verification.

Customer Approval

You review and approve the sample to confirm functionality, compatibility, and quality.

Mass Production

Once approved, we proceed with full-scale manufacturing under strict quality control standards.

Quality Inspection & Delivery

Each batch undergoes comprehensive testing before packaging and shipment to ensure reliability and consistency.

Service Highlights

| Advantage Category | Our Strengths |

|---|---|

| Customization Flexibility | Cable length, connector types, appearance, and materials can all be tailored to your needs. |

| Performance & Quality | Supports up to 12 Gbps; gold-plated contacts and bare copper conductors ensure high speed and stability. |

| Service Efficiency | Fast response for evaluation and sample approval; supports small-batch trial production. |

| Professional Engineering Support | Dedicated technical expertise and application-specific recommendations ensure seamless project integration. |

One-sentence summary:

When facing challenges such as interface compatibility, cable length, or space constraints in server storage, storage array expansion, or high-density backplane deployment, Kingda-Cables’ customization service delivers precise solutions with high performance, reliability, and deployment efficiency.